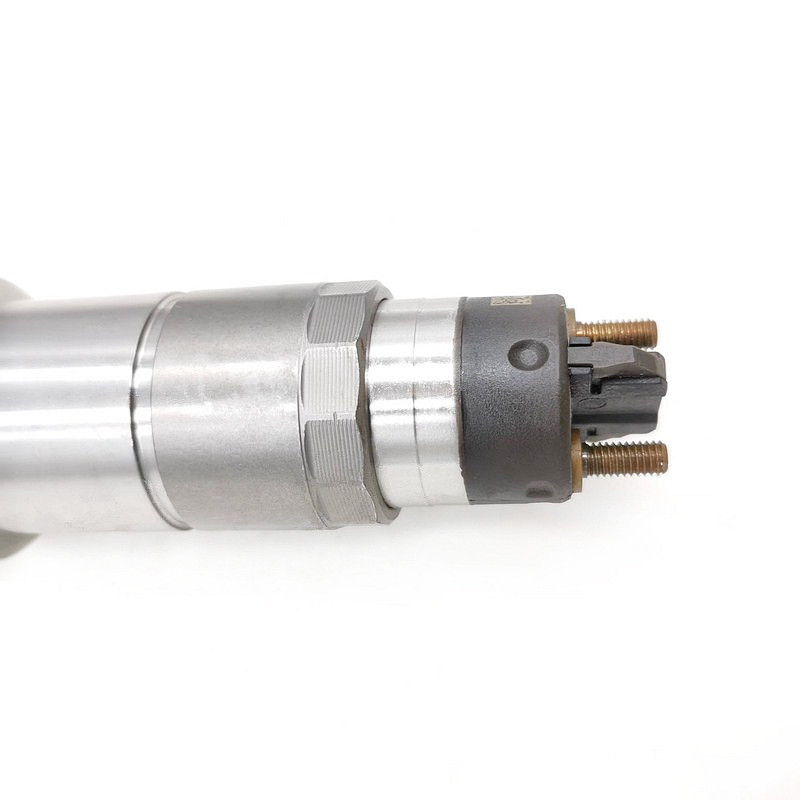

Diesel Injector Fuel Injector 0445120123 Bosch for Cummins Kamaz Kavz Engine

| Produce Name | 0445120123 |

| Engine Model | Cummins 3.9 d / 5.9 d Kamaz 4308-A3 / 4308-H3 4.5 d Kamaz 53605-D3 / 65115-D3 6.7 d KAVZ AURORA 4235 Kavz Kurgan 4235 3.9 / 4.5 d |

| Application | / |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

The specific testing process is as follows :(1) When the rotation speed of the fuel injection pump is 1000 r/min, adjust the position of the fuel supply tooth rod so that the circulating oil volume of the fuel injection pump is 50 mm3, keep the position of the fuel supply tooth rod unchanged, and measure the spray impact force of each hole of the fuel injector under the rotation speed of the fuel injection pump at 800, 1000 and 1200 r/min respectively; (2) Adjust the test bench controller of the fuel injection pump to make the speed of the fuel injection pump run stably at 1000 r/min, adjust the position of the oil supply tooth rod, and measure the spray impact force of each hole of the fuel injector when the circulating oil volume of the fuel injection pump is 50, 60 and 70 mm3/cycle.

In order to meet stringent CO: emission regulations and mitigate the target conflict between nitrogen oxide (NO.) and soot emissions, it is necessary to develop efficient power plants. It is a challenge for diesel engines to meet current and future European emissions standards. High exhaust gas recirculation (EGR) rate and high booster pressure can effectively improve the conflict between NO and soot emission of diesel engines under partial load operation. The optimal injection strategy is combined with the digital injection pattern to reduce particle emission and combustion noise. Matsumoto et al. have shown that optimizing fuel injection systems is an important factor in achieving these goals. The aim of the ongoing experimental research is to integrate the pressure modulation system into the diesel injector of passenger car so as to achieve efficient injection modeling with the same complexity of the system.