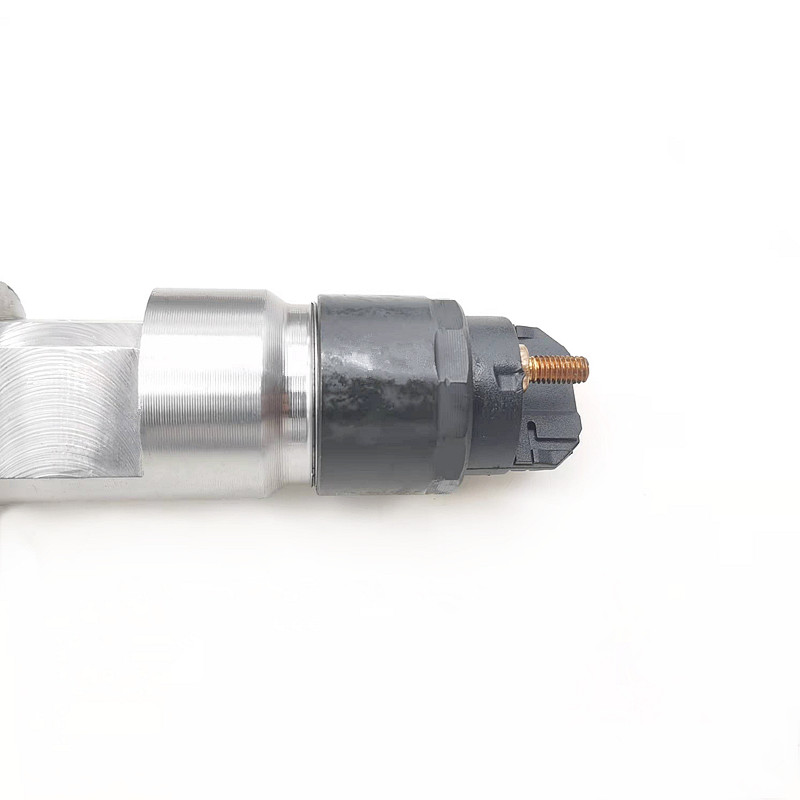

Diesel Injector Fuel Injector 0445120188 Bosch for Dodge RAM 2500 / RAM 3500 Pickup Truck 6.7L High-Output Cummins

products detail

Used in Vehicles / Engines

| Product Code | 0445120188 |

| Engine Model | / |

| Application | Gaz Deutz Yamz Engine |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Warranty | 6 months |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

| Delivery Method | DHL, TNT, UPS, FedEx, EMS or Requested |

Our advantage

Developing the Model of Fuel Injection Process Efficiency Analysis for Injector for Diesel Engines (part 5)

Because of disintegration, the fuel jet is transformed into a fuel spray with a certain drop size distribution. Furthermore, the drop diameter is a random continuous quantity, i.e. it can take any value in the interval of its definition. In this regard, the fuel spray should be considered not only as an accumulation or a set of drops, but as a static aggregate of drops of various sizes.

According to the distribution laws considered, at least two parameters are required to study the drop size spectrum of the atomized fuel: the average drop diameter and the jet distribution characteristics (dispersion, range).

A Sauter mean drop diameter method was selected. It represents a ratio of the total volume of all the drops to their total surface.

Fuel atomization depends on the Weber number, which is a dimensionless quantity establishing a relationship between three parameters that influence the fineness of liquid atomization and found from the expression

(2) :DP -Pressure drop, 2 H/ m between the nozzle orifice and medium to which the injection is performed c d -nozzle orifice diameter, m ; s – fuel surface tension, N/m One of the basic laws of capillary phenomena influencing the fineness of atomization is the Laplace law.

A dimensionless criterion links four parameters that influence the fineness of fuel atomization (3)rT - fuel density kg/m3 between the nozzle orifice and medium to which the injection is performed; c d - nozzle orifice diameter, m ; σ – fuel surface tension, N/m, mT – fuel dynamic viscosity, Ns/m2

A significant effect on the fuel atomization is caused by the rate at which the liquid flows out of the nozzle orifice. The rate of flowing out fuel at which the disintegration begins immediately at the nozzle orifice depends on a number of factors (4):