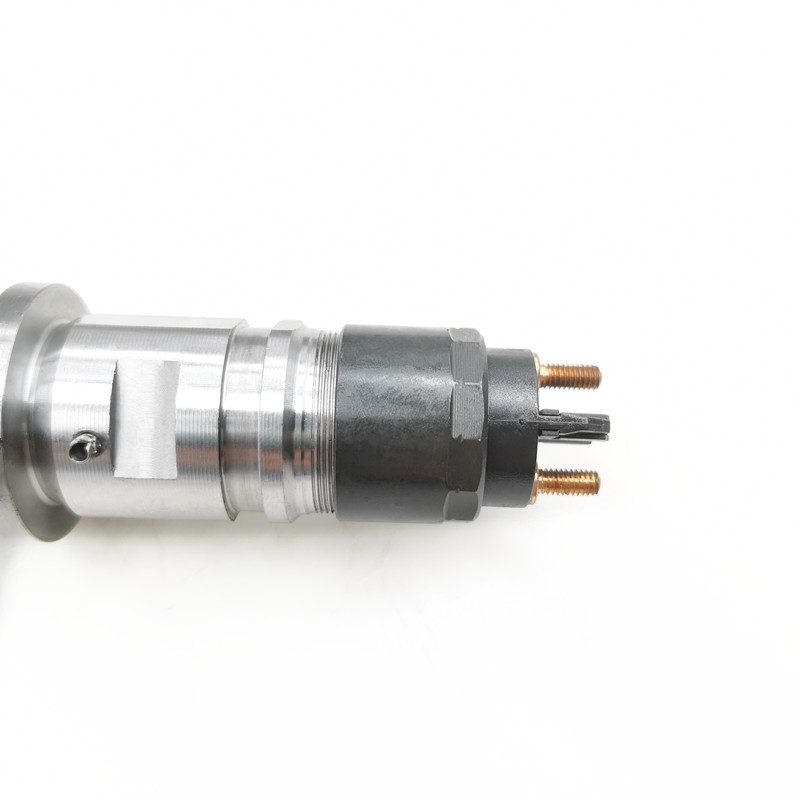

Diesel Injector Fuel Injector 0445120204 Bosch for Dodge RAM 3500 / 4500 / 5500 Pickup Truck 6.7L Cummins Turbo Diesel I6 Enginel

products detail

Used in Vehicles / Engines

| Product Code | 0445120204 |

| Engine Model | / |

| Application | Gaz Deutz Yamz Engine |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Warranty | 6 months |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

| Delivery Method | DHL, TNT, UPS, FedEx, EMS or Requested |

Structure and working principle of fuel injector for marine diesel engine

- As one of the key components of the marine diesel engine injection and combustion system, the fuel injector will pump the high-pressure fuel pumped out by the high-pressure oil pump into the cylinder in an atomized state to achieve good cooperation with the compressed air and the combustion chamber. The fuel injector can't work well, which will lead to problems such as increased fuel consumption of the diesel engine, reduced output power, and carbon deposits in the cylinder. The head of the injector is in direct contact with high-temperature gas, and the working conditions are very harsh. Therefore, special attention should be paid to the injector in daily maintenance.

The core component of the general marine diesel engine injector structure is the needle valve coupling, including the needle valve and the needle valve body. The needle valve is pre-tightened by the pressure regulating spring, and the high-pressure fuel enters the injector body through the oil inlet passage, and generates thrust on the pressure-bearing cone surface. When the thrust of the needle valve exceeds the pre-tightening force of the pressure regulating spring, the needle valve opens, and the high-pressure fuel is sprayed into the cylinder from the injection hole in the form of atomization. At this time, the fuel pressure is the opening pressure of the injector valve. When the thrust acting on the pressure-bearing cone surface is lower than the opening pressure of the valve, the needle valve is closed and the entire atomization process ends. In the fuel injector, a small amount of fuel will flow out from the gap between the needle valve and the needle valve body to lubricate the needle valve body, and then enter the oil return pipe through the inner hole of the oil return passage bolt, and flow back to the fuel oil again. box.

Write your message here and send it to us