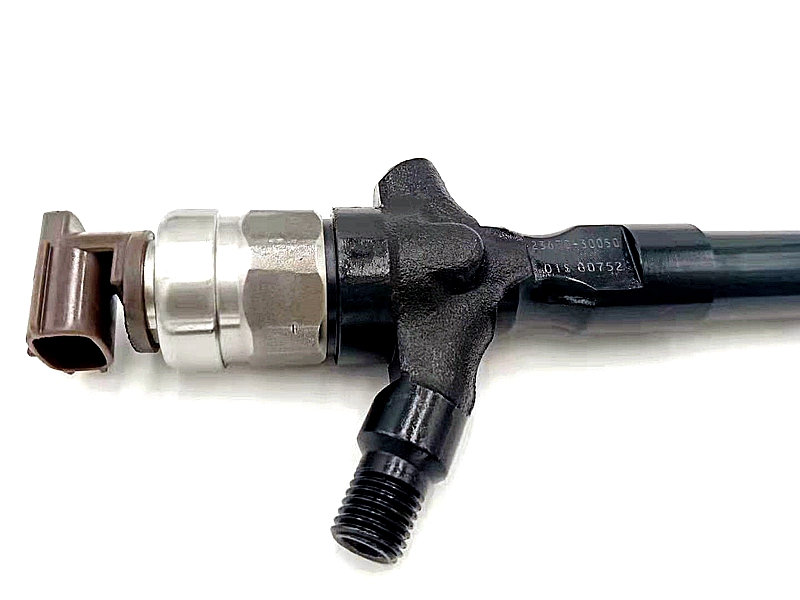

Diesel Injector Fuel Injector 23670-30050 095000-5660 Denso Injector for Toyato Hiace, Toyato Hilux

products detail

Used in Vehicles / Engines

| Product Code | 23670-30050 095000-5660 |

| Engine Model | 1KD-FTV, 2KD-FTV |

| Application | Toyato Hiace, Toyato Hilux |

| MOQ | 6 pcs / Negotiated |

| Packaging | White Box Packaging or Customer's Requirement |

| Warranty | 6 months |

| Lead time | 7-15 working days after confirm order |

| Payment | T/T, PAYPAL, as your preference |

Injector dripping oil

Poor sealing of needle valve cone. Part of it is caused by the high-frequency repeated impact of the needle valve cone surface on the needle valve body cone surface; on the other hand, it is the result of long-term wear of impurities in diesel oil. Plastic deformation of the cone surface of the needle valve, cold work hardening, surface cracks, increase of the needle valve lift, etc., resulting in a decrease in sealing performance, formation of carbon deposits at the dripping nozzle holes of the fuel injectors, and even blockage of the nozzle holes. When the oil dripping is serious, there will be intermittent crackling sound in the cylinder, which will increase the fuel consumption of the diesel engine, reduce the working efficiency, and cause insufficient combustion and black smoke.

Maintain the fuel injector assembly on time. Disassemble the fuel injector, apply a small amount of chromium oxide on the cone surface of the needle valve to grind the cone surface, then immerse in 70C diesel oil to clean it, and finally assemble the fuel injector for spray test testing, if the above phenomenon still occurs, it indicates that the needle valve is relatively worn Seriously, new parts should be replaced in time. During the maintenance process, the fuel injector parts should be handled with care to avoid contact with sulfur. When applying abrasive paste, avoid spraying it into the spray hole. If there is no abrasive paste, it can be replaced with toothpaste or engine oil.

Regularly check the fuel injector, do a good job of maintenance work, check whether the atomization effect is good, strengthen the inspection and adjust the valve opening pressure, check the tightness of the fuel injector, and find the worn parts of the fuel injector and the failed seal The ring should be replaced in time to ensure the normal operation of the ship