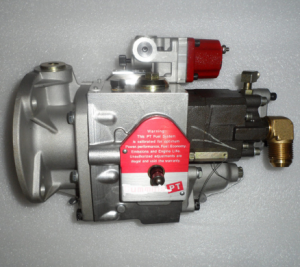

Genuine Quality Diesel High Pressure Injection Pump Head Rotor 9461080408 9 461 080 408 for VE Fuel Pump

products description

| Reference. Codes | 9 461 080 408 |

| Application | / |

| MOQ | 2PCS |

| Certification | ISO9001 |

| Place of Origin | China |

| Packaging | Neutral packing |

| Quality Control | 100% tested before shipment |

| Lead time | 7~15 working days |

| Payment | T/T, L/C, Paypal, Western Union or as your requirement |

The difference between VE pump head and Lucas pump head

1. Structural differences:

VE pump head:

Usually has a simple structure, fewer parts, small size and light weight. Most of them are composed of an aluminum pump body and a distribution head, which contains an oil pump, an oil pressure regulating valve, a transmission shaft, a flat cam, an automatic oil supply adjustment mechanism, etc. The plunger is a key component that not only compresses the oil but also distributes the oil, and realizes the supply of fuel through its reciprocating and rotating motion.

Lucas pump head:

The structure may be different from the VE pump head, but it usually also includes the basic processes of oil inlet, oil pumping and oil distribution.

May have different control and adjustment mechanisms to adapt to different engine requirements and fuel characteristics.

2. Differences in operation and working principles:

VE pump head:

Oil inlet process: When the concave part of the flat cam contacts the roller, the plunger is pushed to the left by the spring, and the diesel enters the plunger cavity through the oil inlet groove and the oil inlet hole.

Oil pumping and oil distribution process: When the flat cam turns to the convex part and contacts the roller, the plunger moves to the right, compresses the diesel and enters the injector through the oil distribution hole and the oil outlet hole.

Fuel stop process: When the oil drain hole is connected to the inner cavity of the injection pump body, the diesel pressure drops and the fuel supply stops.

Lucas pump head:

Since there is no specific Lucas pump head operation data, we can assume that its fuel supply, pumping and fuel stop process may be similar to the VE pump head, but the control details and specific mechanisms may be different.

3. Debugging and maintenance:

VE pump head:

Debugging may involve the adjustment of the maximum fuel supply, the adjustment of the injection timing, and the adjustment of the governor. Maintenance requires regular inspection of the cleanliness of the fuel, the wear of the pump head, and the condition of the lubricating oil.

Lucas pump head:

The specific steps of debugging and maintenance may be different from those of the VE pump head, but the basic idea may be similar, that is, to ensure stable fuel supply, accurate injection, and reliability of system operation.