Thailand is an important automobile production base in the world, which is reflected in the fact that Thailand’s annual automobile production is as high as 1.9 million vehicles, the highest in ASEAN; more importantly, in 2022, the total export value of Thailand’s automotive parts industry reached 1.31 trillion baht, an increase of 8.2%, accounting for about 12.3% of GDP; the export value of parts is the highest in ASEAN and ranks 14th in the world, and the export value of automobile tires has reached the second place in the world. It can be said that the automotive parts manufacturing industry has promoted Thailand to become a modern automobile industry production base.

basic situation

Since 1963, the Thai government has been promoting the development of the automotive parts industry. Initially, Thai government departments focused on introducing measures to support investment in the production and use of domestic automotive parts, especially the increase in import tariffs on complete vehicles (Complete Built-Up: CBU) and complete knock-down (Complete Knock-Down: CKD). Subsequently, the Board of Investment (BOI) issued measures such as corporate income tax exemption and machinery import tariff exemption to attract foreign investors to set up production bases in Thailand.

In addition, the Thai government also determined the proportion of locally produced auto parts used in automobile manufacturing (local content requirement: LCR). This requirement has been cancelled, but the proportion of locally produced parts in the total value of auto parts used in the production of Thai passenger cars is still as high as 60-80%; environmentally friendly cars and pickup trucks reach 90%, and motorcycles use almost all locally produced parts. Currently, Thailand’s free trade agreements with other countries such as the ASEAN Free Trade Agreement (AFTA), the Thailand-Japan Economic Partnership Agreement (JTEPA), and the Thailand-Australia Free Trade Agreement (TAFTA) have led to a decline in CBU and CKD imports with higher tariff rates.

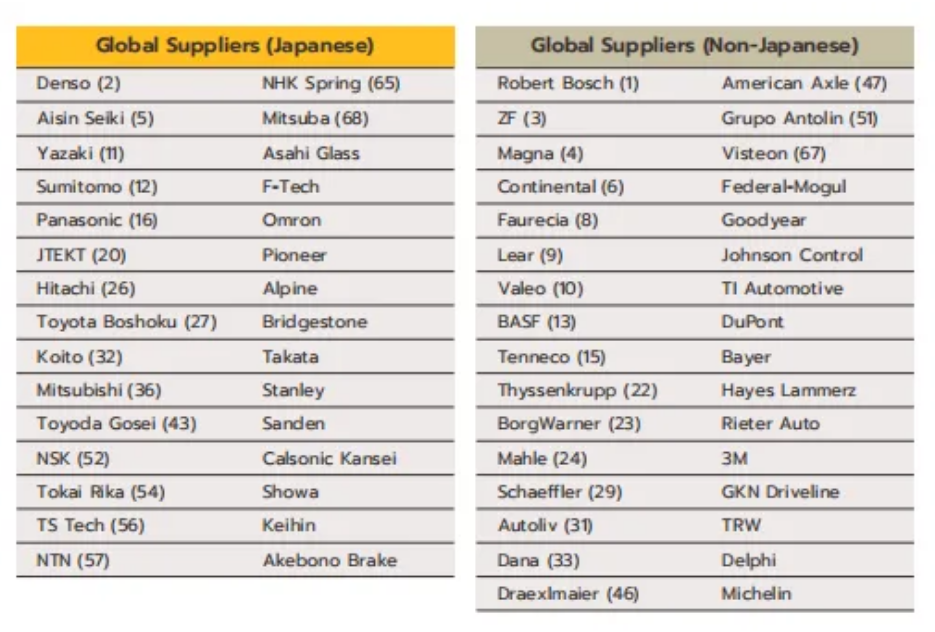

Thai and foreign investors continue to invest in the auto parts industry in Thailand. Important local companies and joint ventures in Thailand include Thai Summit Auto Parts Co., Ltd., Sammitr Auto Parts Co., Ltd., Somboon Advance Technology Plc., Thai Auto Pressparts Co., Ltd., etc. Globally renowned auto parts suppliers that have set up production bases in Thailand include Bosch, Denso, Magna, Continental, ZF, and Aisin Seiki. Among the important products are:

1) Rubber parts group:

Relying on the domestic supply of natural rubber raw materials in Thailand, such as hoses, belts, fiberglass rims, car tires and other products that require high-level production technology;

2) Powertrain and engine parts:

Among them, the supply chain is complex and the value exceeds 1/3 of the cost of producing internal combustion engine (ICE) vehicles. It is also the group that the Thai government promotes production in the entire supply chain, such as radiators, exhaust pipes, fuel supply systems, fuel tanks, ignition systems, gears, etc.;

3) Electric vehicles:

The Thai government promotes electric vehicle investment in a package form, so automakers gradually apply for investment to promote the production of electric vehicles and parts in Thailand. Batteries, in particular, account for up to 30% of the cost of electric vehicles.

Products and export structure

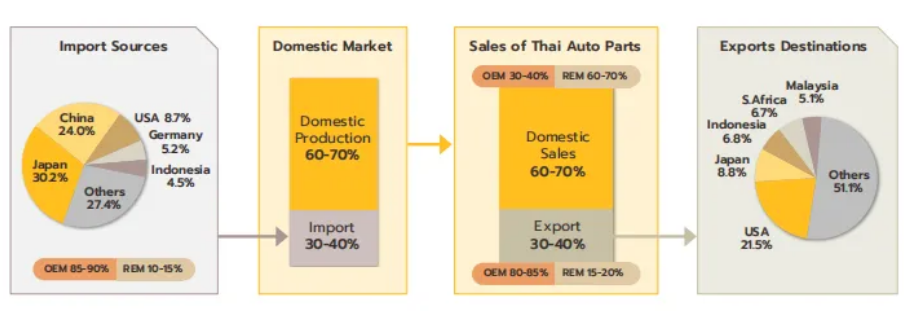

Thailand’s automotive parts manufacturing industry mainly relies on its domestic market, with sales accounting for 60-70%, divided into vehicle assembly (original equipment manufacturers OEM) and automotive parts replacement (replacement equipment manufacturers REM).

OEM: 30-40% of the total output value of Thailand’s parts market

Expanding with the growth of automobile production, more than 80% of which are produced domestically in Thailand, and the rest require advanced technology products from the parent company or overseas parent company suppliers, such as electronic components (microcontroller chips: MCU) for automotive control systems imported from Japan, and internal combustion engine parts and electric vehicle parts imported from China.

REM: 60-70% of the total value of Thailand’s domestic parts market

The REM market grows in the same direction as the cumulative number of registered vehicles, depending on the period of use and the demand for replacement parts (spare parts). REM has a variety of distribution channels, including dealers/car dealers’ repair service centers, auto parts wholesale and retail stores, and general repair shops. In terms of the value of imported parts, REM accounts for 10-20% of the total value of imported parts, most of which are imported from Japan (accounting for 43% of the total REM parts imports), as well as China (17%) and the United States (8%).

Parts exports account for 30-40% of the total revenue of the parts manufacturing industry, of which OEM parts account for 80-85% of the total exports and REM parts account for 15-20%. The main parts exported by Thailand are engines, wiring harnesses, bodies, mirrors, gear units, tires and rubber parts.

Thailand is considered a highly competitive country in the field of automotive parts worldwide. It uses supply chains to achieve economies of scale and the quality of the parts produced is recognized by automobile manufacturers. In addition, Thailand also has the location advantage of parts production, making it an important parts production base in the world. In 2021, Thailand’s exports of parts (all types) were the highest in ASEAN and ranked 14th in the world. The main exported parts were automobile tires (second in the world), other motorcycle parts (excluding engines and vehicle tires) (ranked 3rd), engines (ranked 13th) and other automobile parts (excluding engines and tires) (ranked 15th). Most of Thailand’s auto parts are exported to ASEAN automobile production bases, namely Indonesia, Malaysia, Vietnam and the Philippines, which together account for 22% of the total auto parts exports, followed by the United States (22%) and Japan (9%).

Post time: Jun-14-2024